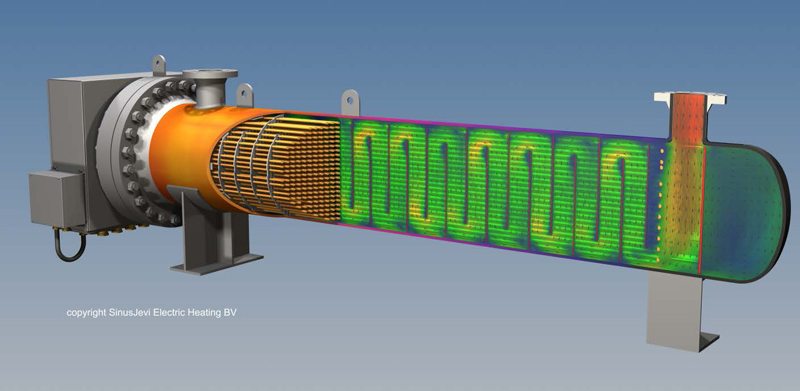

Flow Simulation

By implementing CFD (Computational Fluid Dynamics) software Sinus Jevi has obtained the ability to optimise heater designs.

An electric process heater uses electric powered heating elements to pass the energy to the medium. Electric heating elements provide 100% of the power to the medium. Hereby the flow is of great importance. A disruption, the forming of eddies or flow stagnation will cause an effect on the heat transfer with possibilities of elements to overheat.

Visualising the physical aspects of a heater will lead to more innovative designs and greater product efficiency. It provides the possibility to improve power distribution by optimising baffle design and baffle pitch. This will ensure that heating element temperatures remain at acceptable levels under normal operating conditions. The optimised heat transfer will prevent hot spots from occuring on the element surface.

For process heater design the CFD studies will give greater insight in temperature, flow and pressure drop characteristics. This can be applied to both normal and low flow situations.